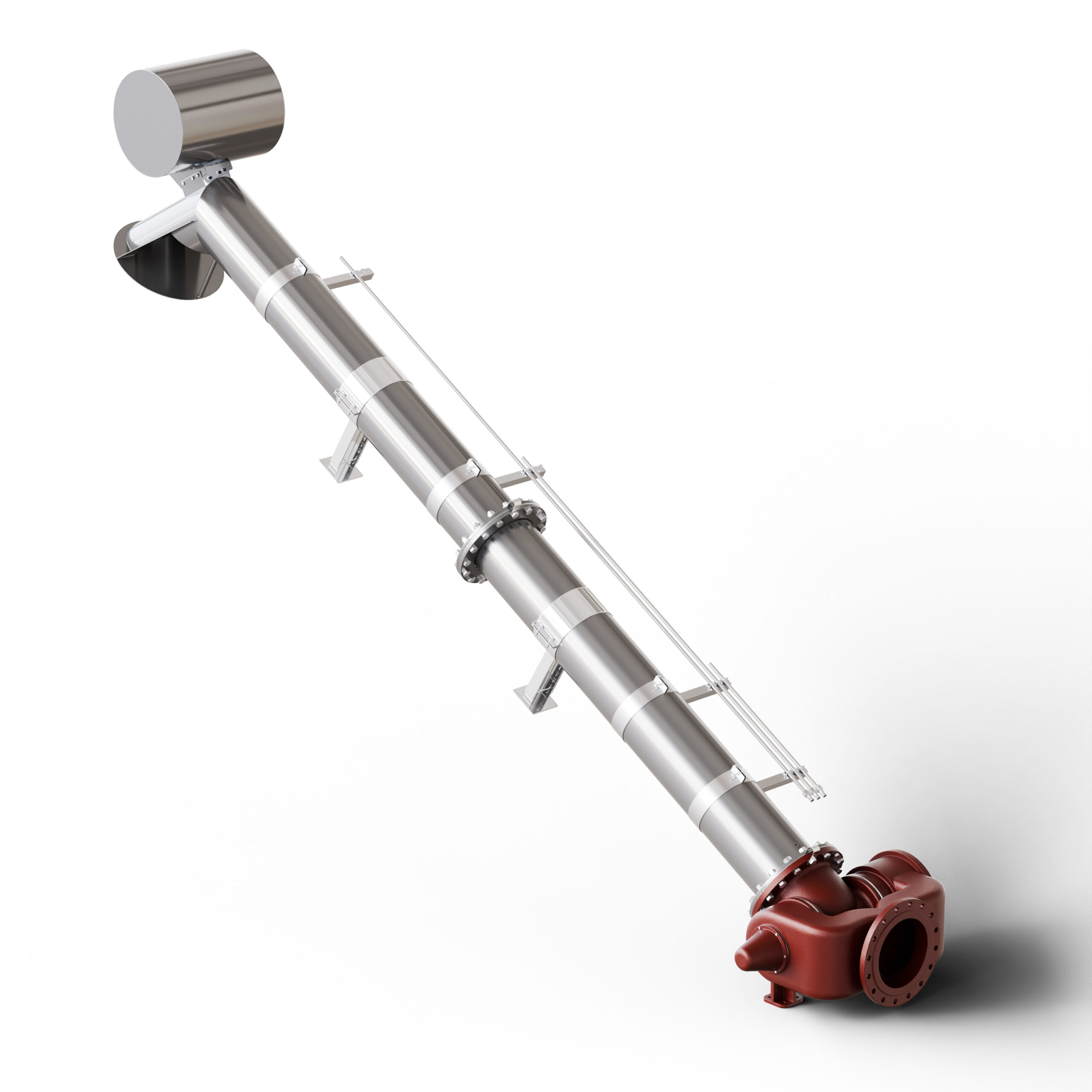

Floating Suction

Floating suction is a withdrawal system designed to extract only the top layer of a liquid stored in a tank. By staying at the surface with the help of a float, it enables the recovery of the purest product while avoiding deposits or particles present at the bottom of the tank.

Benefits

- Withdraws the purest product: ideal for kerosene or sensitive fuels (SAF, JET A-1, etc.)

- Reduces settling time before withdrawal by up to 70%

- Preserves equipment by reducing clogging of downstream filters

- Versatile: compatible with various petroleum products (Jet A1, diesel, crude oil, etc.)

- Facilitates sampling at different levels for rigorous quality control

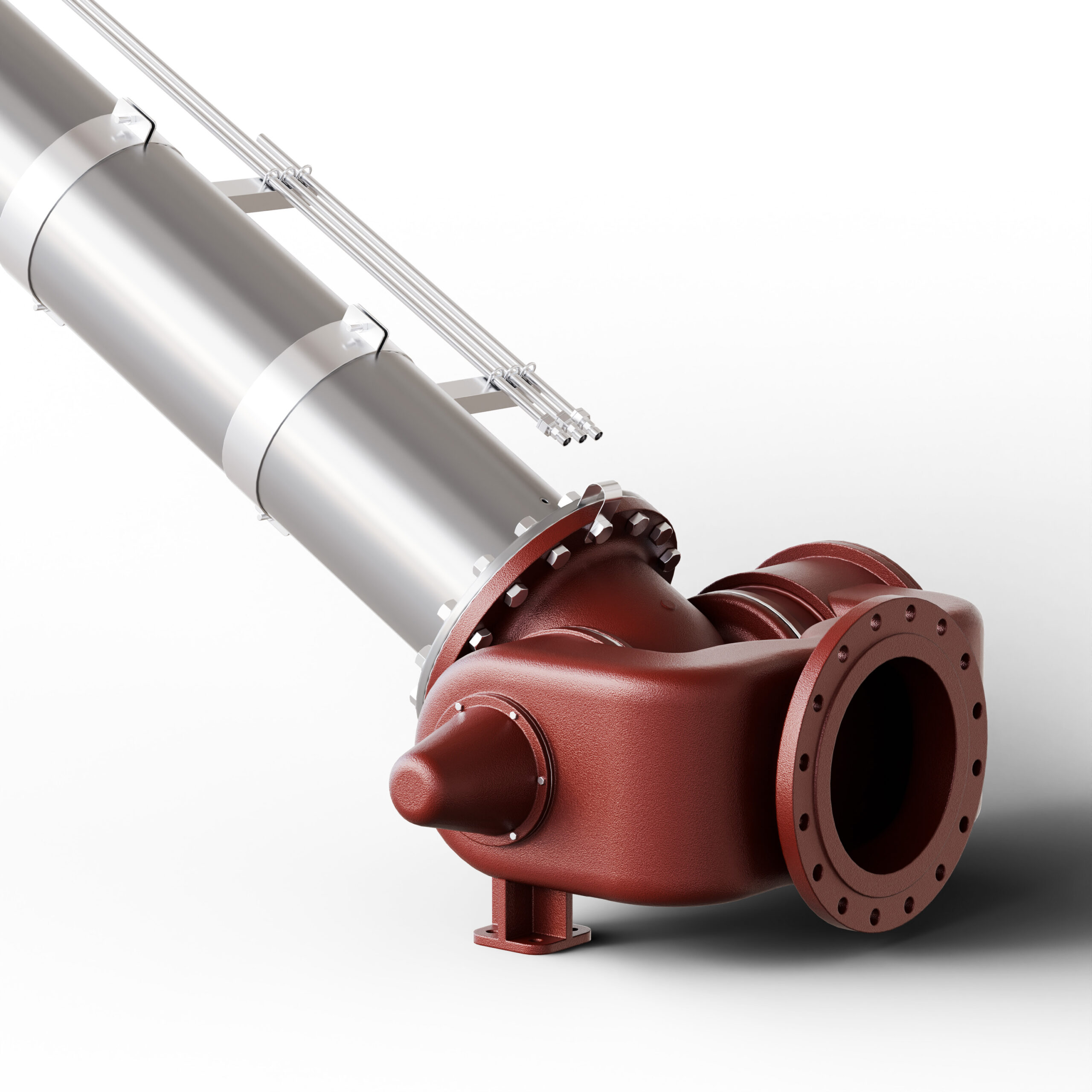

- Robust and reliable system thanks to the symmetric rotary joint T2000 for better stress distribution

- Protects the withdrawal pump: the symmetric rotary joint design reduces pressure losses

- Compliant with JIG recommendations for the aviation market

- Adaptable to any volume: diameters ranging from 2” to 30”

Avantages

Installation

The floating suction is installed inside the tank and connected to the withdrawal piping via an ATEX-certified T2000 rotary joint that allows the floating arm to rotate.

Technology

The system consists of a rigid arm equipped with a float that continuously keeps the suction at the surface. The robust and sealed symmetric T2000 rotary joint ensures smooth rotation without loss or stress.

The technology is designed for maximum reliability, even under demanding conditions such as temperature, pressure, and product aggressiveness.

Testability

- Buoyancy test performed via a cable connected between the tank roof and the floating suction

- Position visible through an optional external level indicator

- Option to add a sampling device for quality control at various levels

- Simple mechanical inspections during scheduled maintenance shutdowns

Options

- Double arm for sizes between 2” and 10”

- Floating suction position indicator

- Multi-level sampling (at 1/3 and 2/3 levels)

- Made from aluminum or stainless steel for corrosive products

- “Skimmer” version to collect unwanted product layers by gravity

- Wide range of available diameters: from 2” to 30”

Certifications

- ATEX-certified T2000 rotary joint II 2G c IIB T6 (-20 °C to +60 °C)

- Materials compliant with JIG requirements for aviation fuels

Key Information

- Tank diameter

- Tank type (horizontal / vertical)

- Tank configuration (fixed roof, floating roof, presence of floating cover)

- Type of stored product

- Operating conditions (temperature, pressure)

- Desired withdrawal height

- Desired withdrawal flow rate

- Specific constraints (corrosion, aviation compatibility, etc.)

Technology

DOCIL Sensor

The DOCIL sensor comprises a glass cone and an electronic circuit with, among other things, an infrared luminous signal transmitter and a receiver.

The DOCIL sensor works on the optical reflection/refraction principle.

DOCIL sensor characteristics

Accuracy

0.1s

Response Time

1 ms

ATEX

II 1 G Ex ia IIC T5 Ga

Success Story