Products & Services

Gauging Solutions

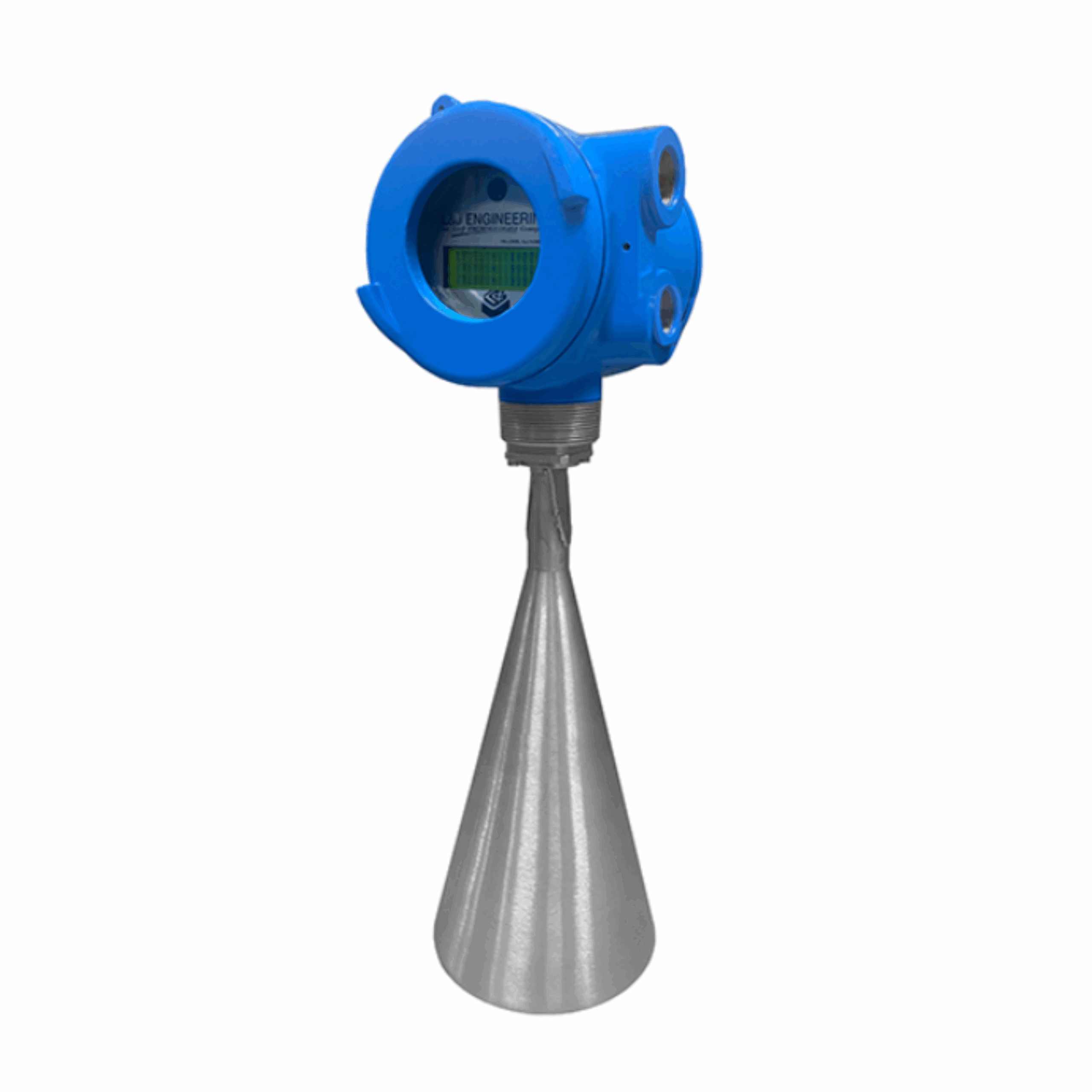

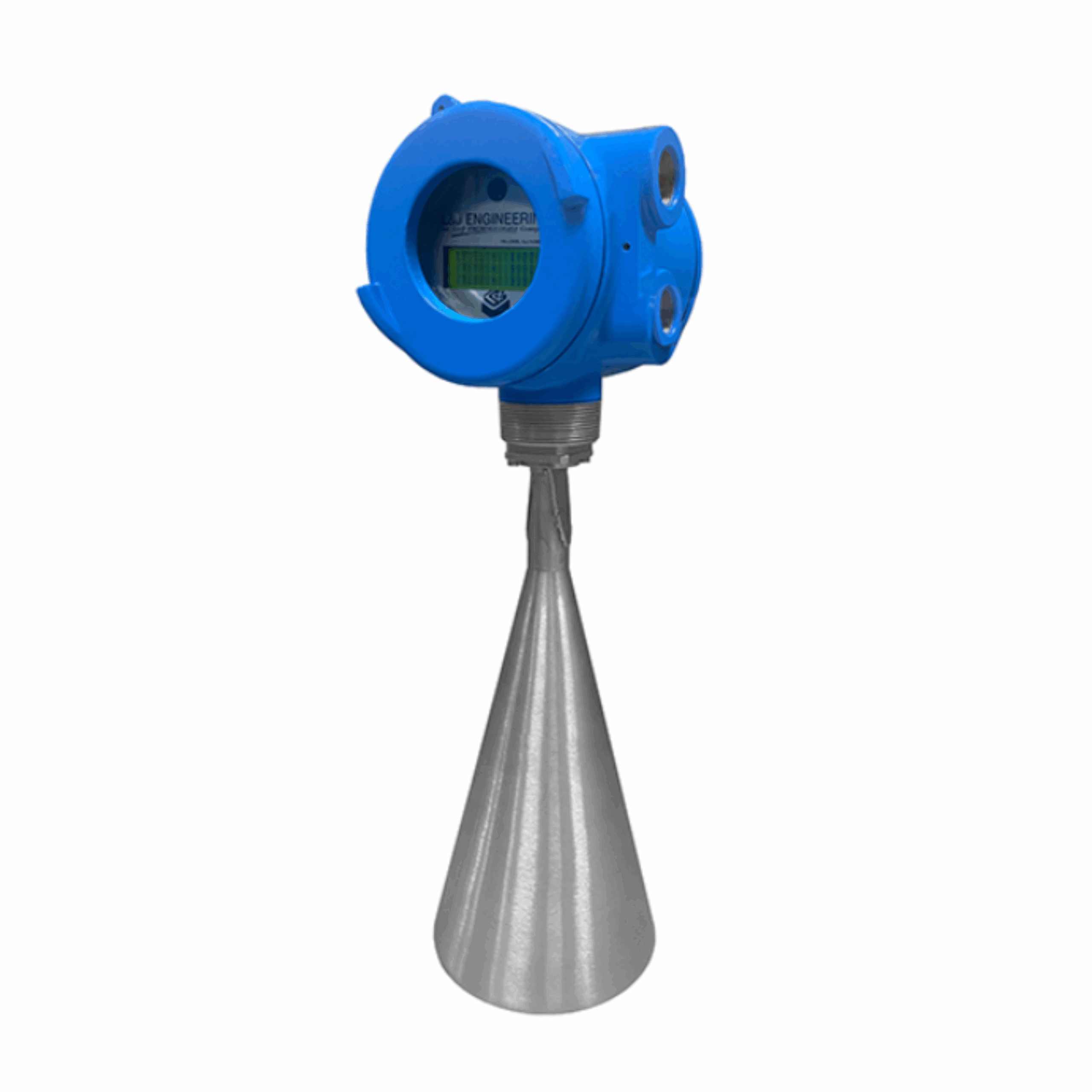

Complete range of level gauges: simple mechanical gauges, level transmitters for mechanical gauges, non-contact radars, motorized servo gauges

MechanicalRadarServo-operatedATEX Multi-protocol

Benefits

Adaptable to all tank types, from the simplest to the most critical; high precision achievable; scalable solutions; optimized maintenance

Advantages

Installation

Roof-mounted installation (or bottom-mounted for mechanical gauges and transmitters), standard flanges with variable sizes based on requirements, ATEX versions available, easy or advanced installation depending on the model.

Technology

- Mechanical (float)

- Magnetic digital encoder

- FMCW radar (10/26 GHz)

- Servo-operated motorized gauge

Testability

- Self-diagnostics

- Manual or software-based testing

- Status LED

- Local display depending on model

Options

- Radar antennas

- Local displays

- Communication modules

- Temperature/density/water bottom sensors

- Analog outputs

Certifications

- ATEX

- IECEx

- Zones 0/1/2

- Lightning and surge protection

- OIML R85 (depending on models)

Required information

- Tank dimensions

- Product type

- ATEX constraints

- Flange type

- Parameter requirements (level only or multi-parameter)