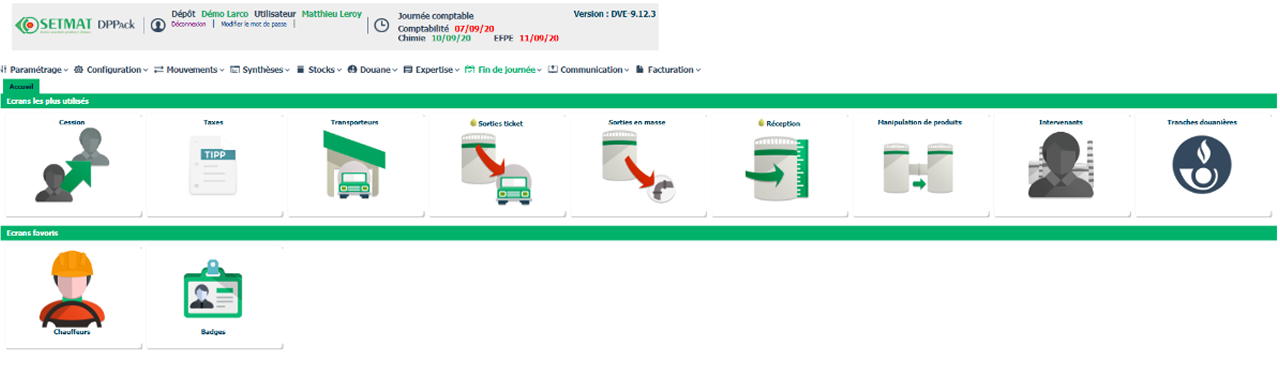

In a sector where efficiency, safety, and compliance are paramount, SETMAT provides a comprehensive response to the challenges faced by depots. Our advanced ERP, DPPACK, along with our intelligent loading bay equipment, optimizes stock management, loading operations, and logistical flows, while ensuring flawless traceability.

Thanks to its modular and scalable approach, DPPACK adapts to all types of infrastructures, enabling operators to gain in productivity, flexibility, and safety.

Why choose SETMAT’s DPPACK?

SETMAT’s DPPACK software suite is designed to integrate seamlessly with existing systems—whether equipment or IT infrastructure. Compatible with most industry standards, it allows operators to modernize their facilities without the need to replace their entire setup.

A streamlined and efficient depot

Automation of operations, reduced waiting times, and optimized loading processes.

Real-time traceability

Instant tracking of inventory, product movements, and customs documents — as well as loading operations, depot access, and quota controls.

Enhanced security

Access control, biometrics, advanced alarm management, and compliance with current regulations.

An intuitive and connected interface

Centralized supervision and simplified access to information for operators and clients, available from any web interface.

A team that listens to you

LARCO supports you throughout the entire project—from defining your needs to implementation—with responsive support and scalable maintenance services.

Optimized stock and flow management

With DPPACK, manage your inventory with complete peace of mind. The stock management module allows you to:

Detailed tracking of tank products with blend management and quality control.

Optimized storage capacity and anticipation of stockouts.

Automation of regulatory declarations (DREAL, CPDP, customs, etc.).

Detailed tracking of tank products with blend management and quality control.

Benefit

Simplified and centralized management, ensuring fewer errors, greater efficiency, and reduced operational costs.

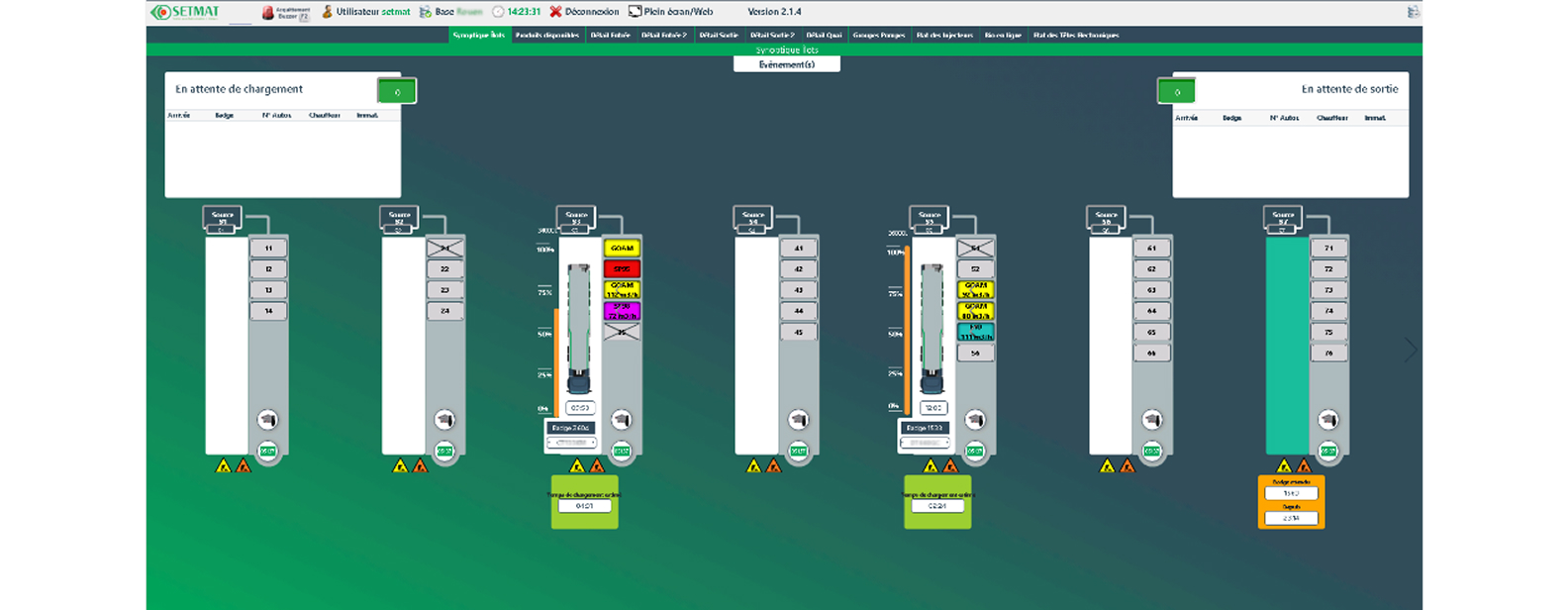

Real-time supervision

With DPPACK, manage your inventory with complete peace of mind. The stock management module enables:

Comprehensive control of operations through a modern web interface.

Real-time visualization of tank filling and truck flow.

Alarm display and monitoring of low tank levels.

Remote intervention when needed to adjust or interrupt a loading operation.

Benefit

Minimize loading time to maximize daily loading capacity and reduce the number of trucks on site.

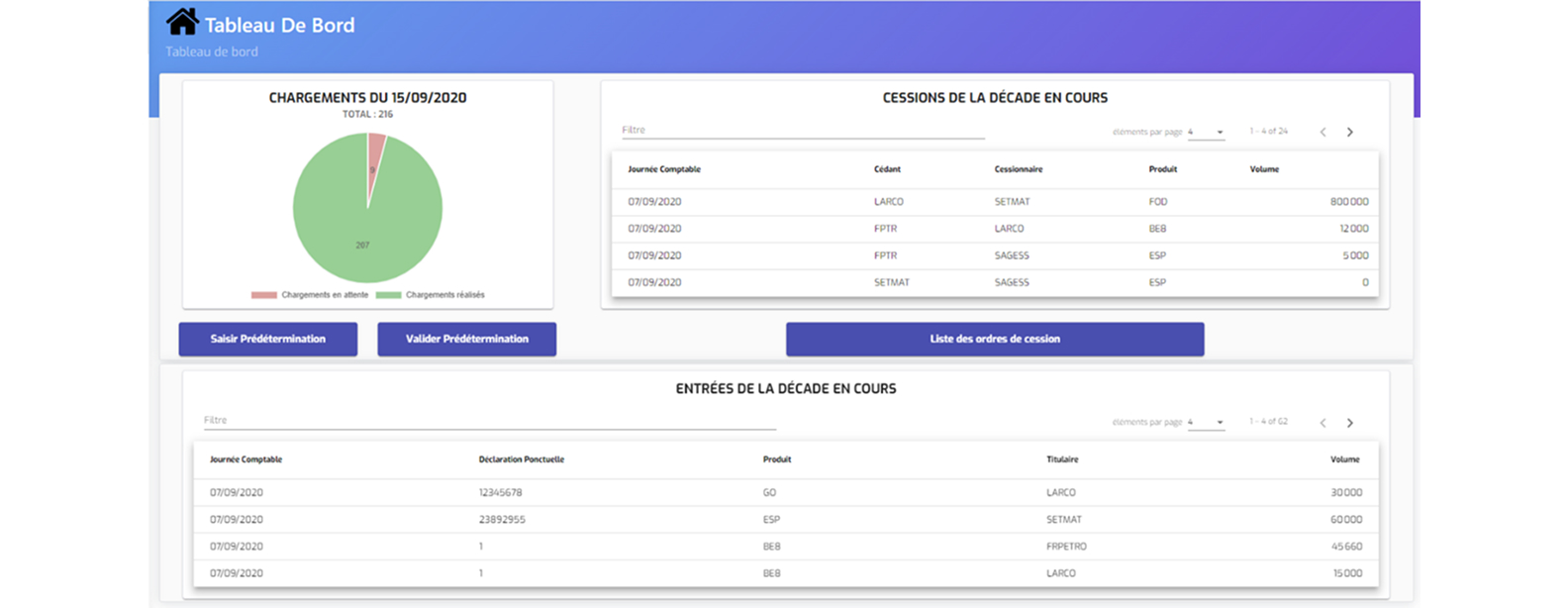

A self-service client portal: WebDPPack

SETMAT facilitates access to information for site clients through WebDPPack, a secure portal that allows them to:

View real-time stock levels and product movements.

Access customs and administrative documents (PSE, PPE, incorporation certificates, etc.).

View delivery notes and issue transfer orders in just a few clicks.

Benefit

Site clients enjoy full autonomy in accessing data and documents, significantly reducing the need to contact depot operators.

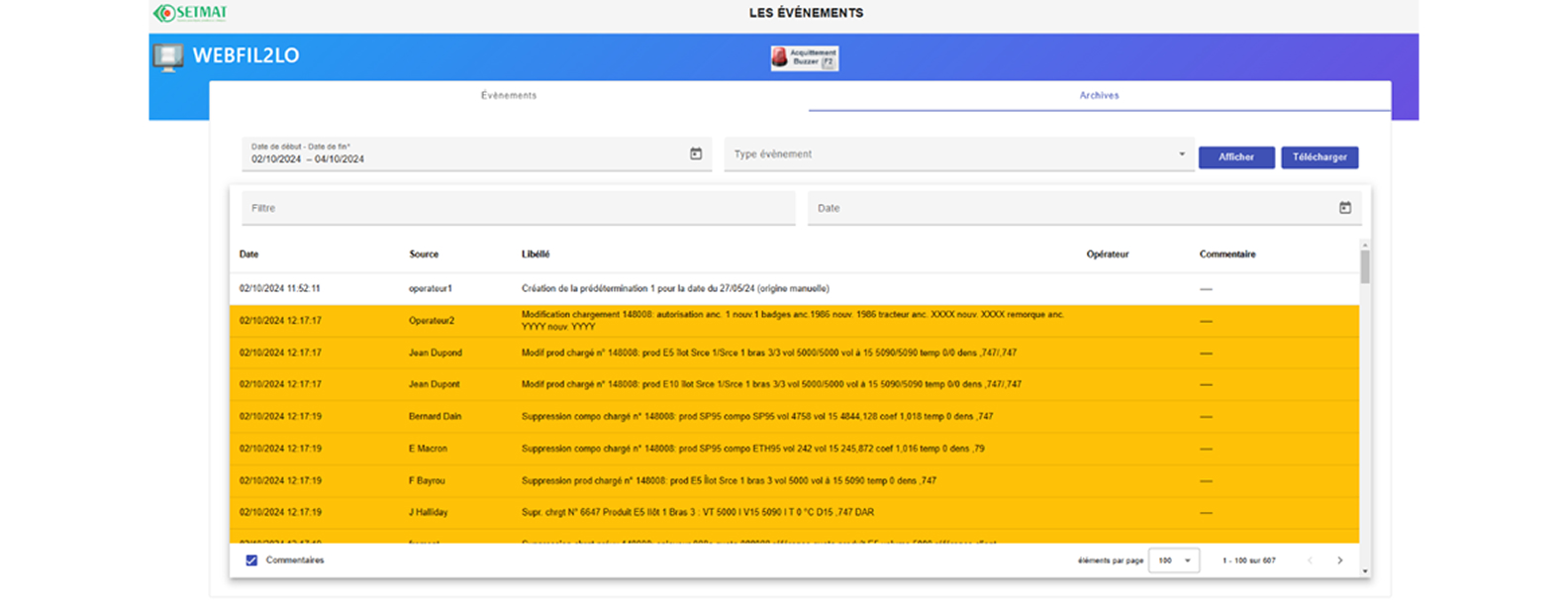

Advanced event management with Webfil2Lo

Webfil2Lo enables the monitoring and analysis of critical events on site by replacing traditional dot-matrix continuous print logs with an intelligent digital system:

Real-time display and archiving of events.

Simplified search with filters and data extraction for analysis.

Alert management and acknowledgment.

Electronic signature of acknowledgments with operator comments.

Benefit

Improved traceability of incident management and its complete digitization.

Protecting people

and the environment

through experience

and innovation

Smart management of loading flows

The driver appointment scheduling module, combined with the queue management system, optimizes the organization of loading operations:

Scheduling of loading slots based on available bays.

Automated queue management to streamline entries and exits.

Maximize bay utilization and organize bay access to avoid conflicts between drivers.

Intuitive interface for carriers, with online booking and slot tracking.

Touchscreen terminal

The touchscreen terminal allows drivers to check in, verify their pre-assignment, and perform tank allocation at the entrance rather than under the loading station, thereby avoiding manual operations at the loading point. Its key features include:

Safety check-in and biometric control.

Entry of the loading plan and selection of pre-assignment.

Automatic overload calculation and volume adjustment.

Verification of driver and vehicle validity dates.

Appointment verification and validation.

Safety check-in and biometric verification.

Benefit

A smoother process, fewer errors, and faster loading management right from the depot entrance.

High-performance loading bay equipment

SETMAT integrates innovative loading bay equipment to ensure precision, speed, and safety during loading operations:

Safety reception and biometric control.

Input of the loading plan and selection of pre-assignment.

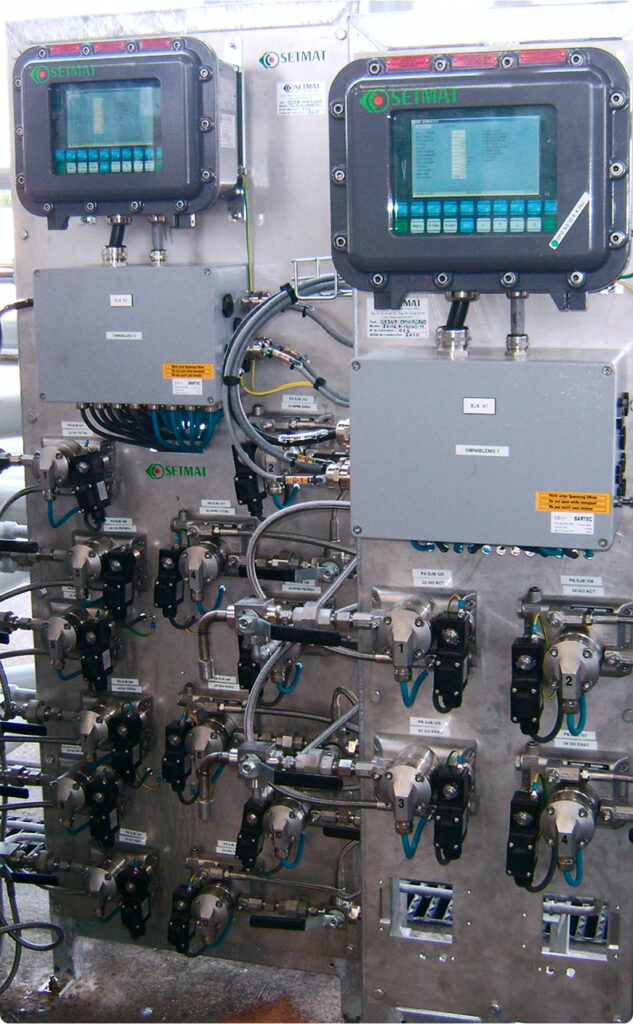

Omniblend: Additivation and Blending System

Up to 12 injectors for precise dosing of additives and colorants, with the ability to control up to 4 biofuel blends.

Compatible with most solenoid valves and meters available on the market.

Robust and compact design, ideal for demanding industrial environments.

AIM Injectors: Performance and Reliability

High-precision metering for optimized dosing.

Stainless steel design for maximum durability.

Flexible installation and simplified maintenance.

These injectors can also be directly assembled with the Omniblend system to create a ready-to-use additivation skid, fully wired and tested in LARCO’s workshop.

PCILOT: Advanced Supervision and Control of Loading Bay Equipment

Enables operation and control of all equipment on a loading bay.

Compatible with a wide range of PLCs, electronic heads, and additivation systems.

Loading data is recorded and can be reviewed at any time.

Real-time transmission of reports to the SETMAT database and supervision system.

MIDI 2500 RF: Control and Identification Terminal

Secure reading of RFID badges.

Backlit screen for improved readability in industrial environments.

ATEX intrinsic safety for use in hazardous areas.

Simple installation with minimal footprint.

Benefit

A simplified interface for the driver managing all loading arms.

Our Services: Expertise, Guidance, and Support

With proven expertise since 1984 in stock management, customs, and loading logistics, the SETMAT team supports you at every stage of your project:

Design Office & Needs Assessment

Our experts analyze your environment to clarify your requirements and offer tailor-made solutions adapted to your infrastructure and constraints.

Implementation Support

We assist you with software setup, hardware configuration, operational testing, and user training, delivering a turnkey solution.

Maintenance Contracts & Technical Support

With the SETMAT solution, LARCO offers you a flexible maintenance contract covering the following scope:

• An online ticketing service for prompt assistance.

• Preventive maintenance to avoid incidents.

• Corrective maintenance to respond to malfunctions.

• Periodic software updates to ensure the ongoing security and performance of your installations.

Real-time transmission of reports to the SETMAT database and supervision system.

Training personnel in the use and first-level maintenance of new equipment.

With the SETMAT solution, you benefit from a dedicated team that will support you throughout the entire lifecycle of your project.

Why Choose the SETMAT Solution?

An All-in-One Solution

A comprehensive suite combining the DPPACK ERP, supervision tools, and intelligent loading bay equipment for centralized and efficient management of your operations.

Reliability and Robustness

Proven solutions that perform reliably in the most demanding industrial environments.

Full Interoperability

SETMAT is compatible with the vast majority of market equipment (electronic heads, control panels, PLCs…) and can easily connect to third-party systems via CPDP or other standard interfaces.

Simplicity and User-Friendliness

An intuitive interface accessible from any browser, requiring no dedicated server or complex installation.

Security and Compliance

Management of access, critical events, and regulatory documentation in accordance with French and European standards.

Local Support

Scalable and regularly updated, SETMAT offers responsive professional support through an easy-to-use web ticketing system.

Trusted by Industry Leaders

Already adopted by numerous French depots for its reliability and the strong support provided by LARCO.