Performance & Safety

in liquid and gas storage, since 1957

Operations Safety & Environment Instrumentation Automation & Software

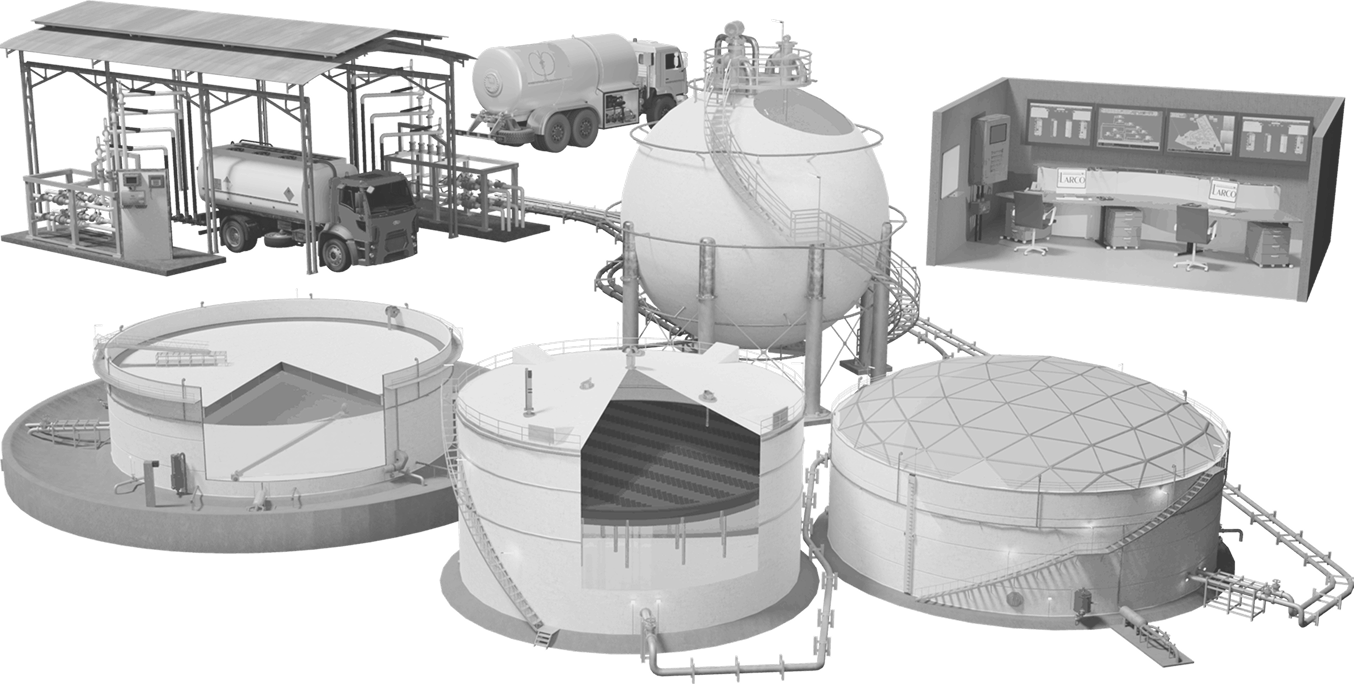

Automate your safety and operations with proven solutions

For over 68 years, LARCO has been manufacturing and marketing a complete range of products for liquid and gas storage tanks.

Our design office and in-depth knowledge of the industrial storage environment make us a key partner in the oil and chemical industries.

Safety & performance

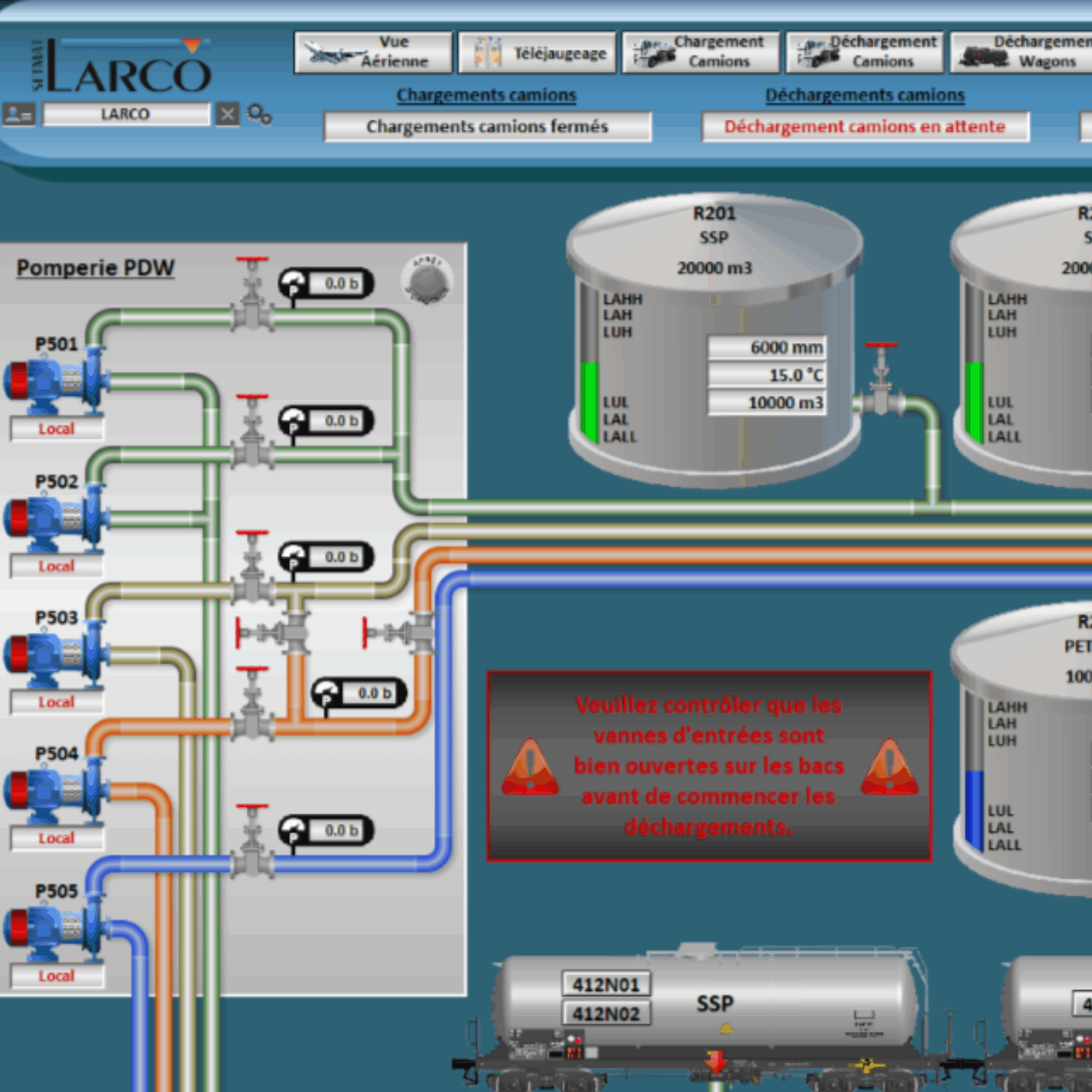

Process and safety automation for oil depots

- Performance

- Safety

- Process

- Automation

- Custom-made solution for liquid storage

LARCO designs custom automation systems to optimize and secure operations at oil depots. Using programmable logic controllers (PLCs), HMI interfaces, and supervision solutions, we deliver a comprehensive and fully tailored response to the site's specific requirements and operational constraints. Our expertise covers both safety automation and process control, with remote access capabilities via a connected gateway.

Larco Safety Box

- Automated Safety Management

- Configurable and Modular

- Overfill and Leak Protection

This automation cabinet is designed to manage up to 10 LARCO overfill prevention or leak detection devices. It is fully configurable via a 12.1-inch HMI, allowing intuitive and efficient setup. All configurations can be performed by LARCO’s local partners.

The cabinet also includes a secure remote access gateway, featuring a unique encrypted certificate and a physical authorization key. This enables fast remote support and software updates while ensuring maximum cybersecurity.

Level Probe for Pressurized Tanks – DOCIL C 500 BTFO

- Anti-Pollution Solutions

- Level Instrumentation for Liquid Storage

- Turnkey Solutions for Liquid Storage

The DOCIL C 500 BTFO probe is designed for pressurized tanks such as LPG spheres or liquefied gas storage tanks. It triggers an alarm as soon as a preset level threshold is reached, preventing overfilling and overpressure.

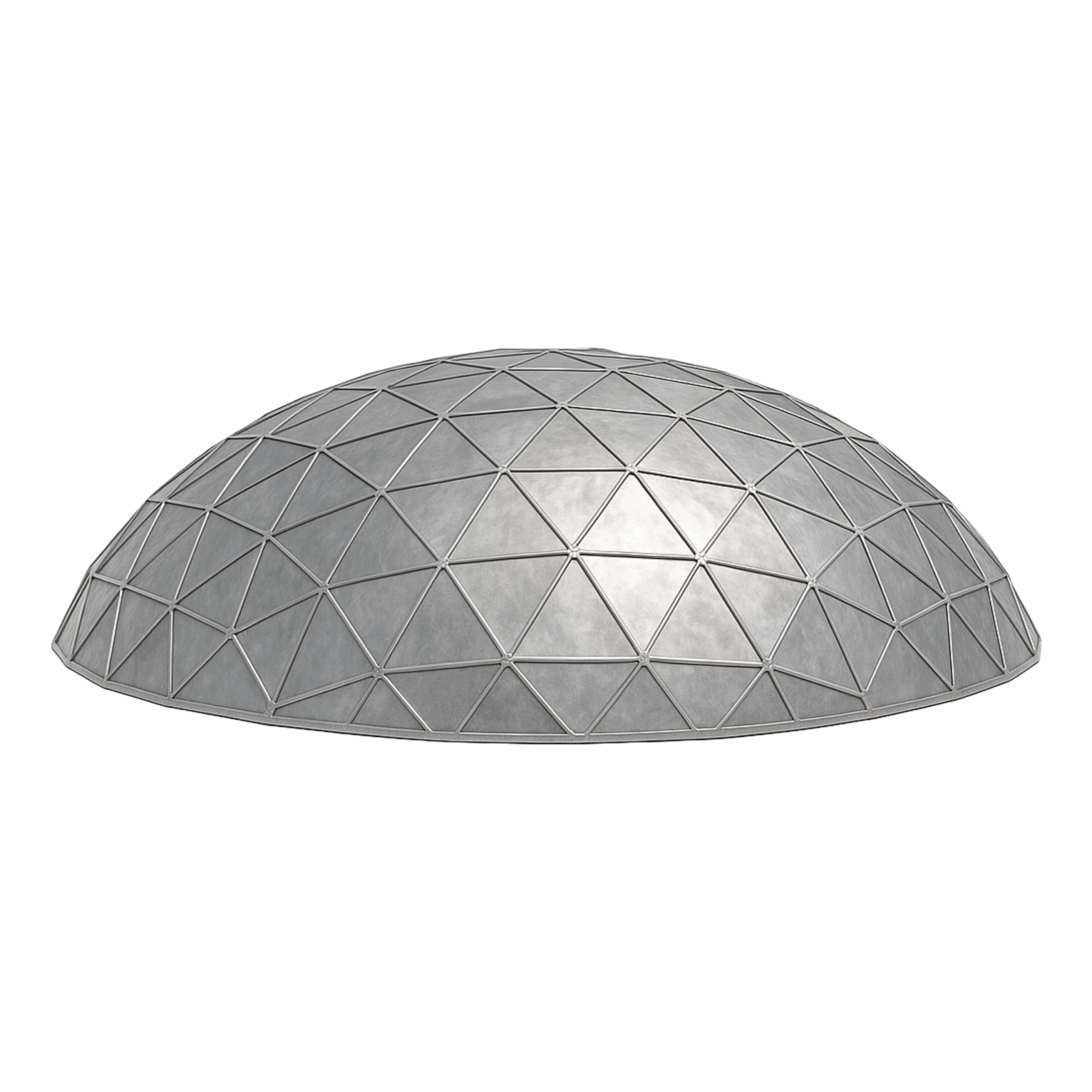

Geodesic Dome

- Safety

- Combating Air Pollution

- Mechanical Equipment for Storage Tanks

Geodesic domes for fuel storage tanks are self-supporting roofs designed to cover large-capacity cylindrical tanks. They protect the fuel from weather conditions, reduce evaporation losses, and enhance the overall safety of the site. Their triangulated design ensures a lightweight, durable structure that can withstand environmental loads.

Breather valve

- Storage Tank Mechanical Equipment

The breather valve is a safety device designed to regulate the pressure inside hydrocarbon storage tanks. It compensates for pressure variations caused by product movement or temperature changes, while ensuring a perfect seal during normal operation.

Level indicator gauge

- Level Instrumentation for Liquid Storage Boosters

The strip level gauge is a simple and reliable mechanical gauging system with an accuracy of ±25 mm. It provides instant visual indication of the product level in a tank. Operating without electricity, it offers direct on-site reading, even in the absence of a control room.

DOCIL C400 Overflow Prevention Probe

- Automated Safety Management

- Configurable and Modular

- Overflow and Leak Prevention

The DOCIL C400 is an overfill protection probe for liquid hydrocarbons. It is equipped with an optical sensor that, when immersed in the product, triggers an alarm.

- Enhances storage and depot safety

- 3 adjustable detection levels

- ATEX & SIL2 / SIL3 certified

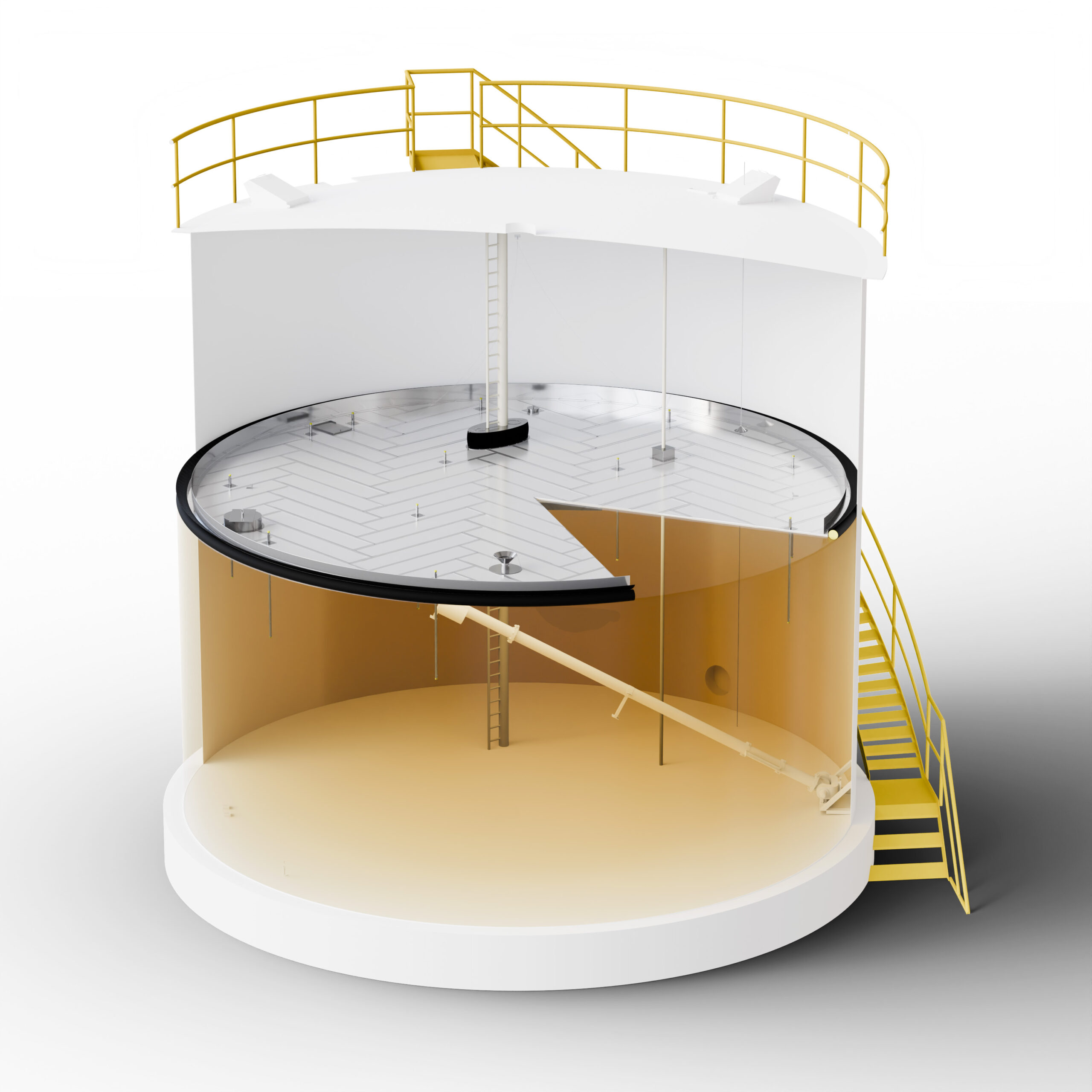

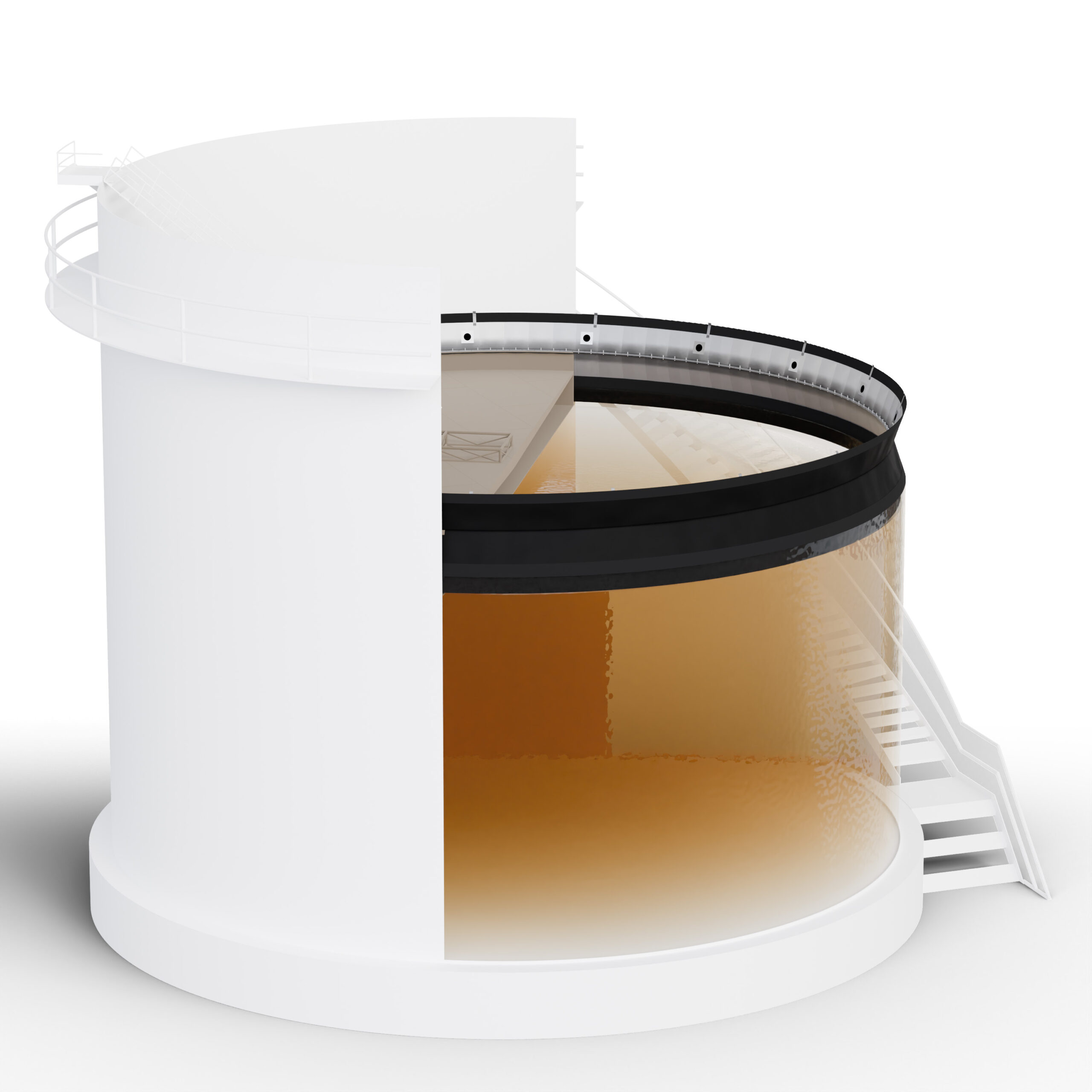

Floating Screen: COVERFLOTE

- Security

- Anti Air Pollution

- Storage Tank Mechanical Equipment

- Exploitation Boosters

The COVERFLOTE® is an internal floating cover designed for installation inside fixed-roof tanks storing liquids that may evaporate or oxidize upon contact with air. Made of self-floating panels, the COVERFLOTE® remains in constant contact with the liquid surface, eliminating the formation of any vapor phase between the panels and the product.

Its peripheral seals adapt to irregularities in the tank wall, ensuring a tight fit. This design reduces product evaporation by up to 98%, significantly lowering VOC emissions while enhancing both site safety and financial performance.

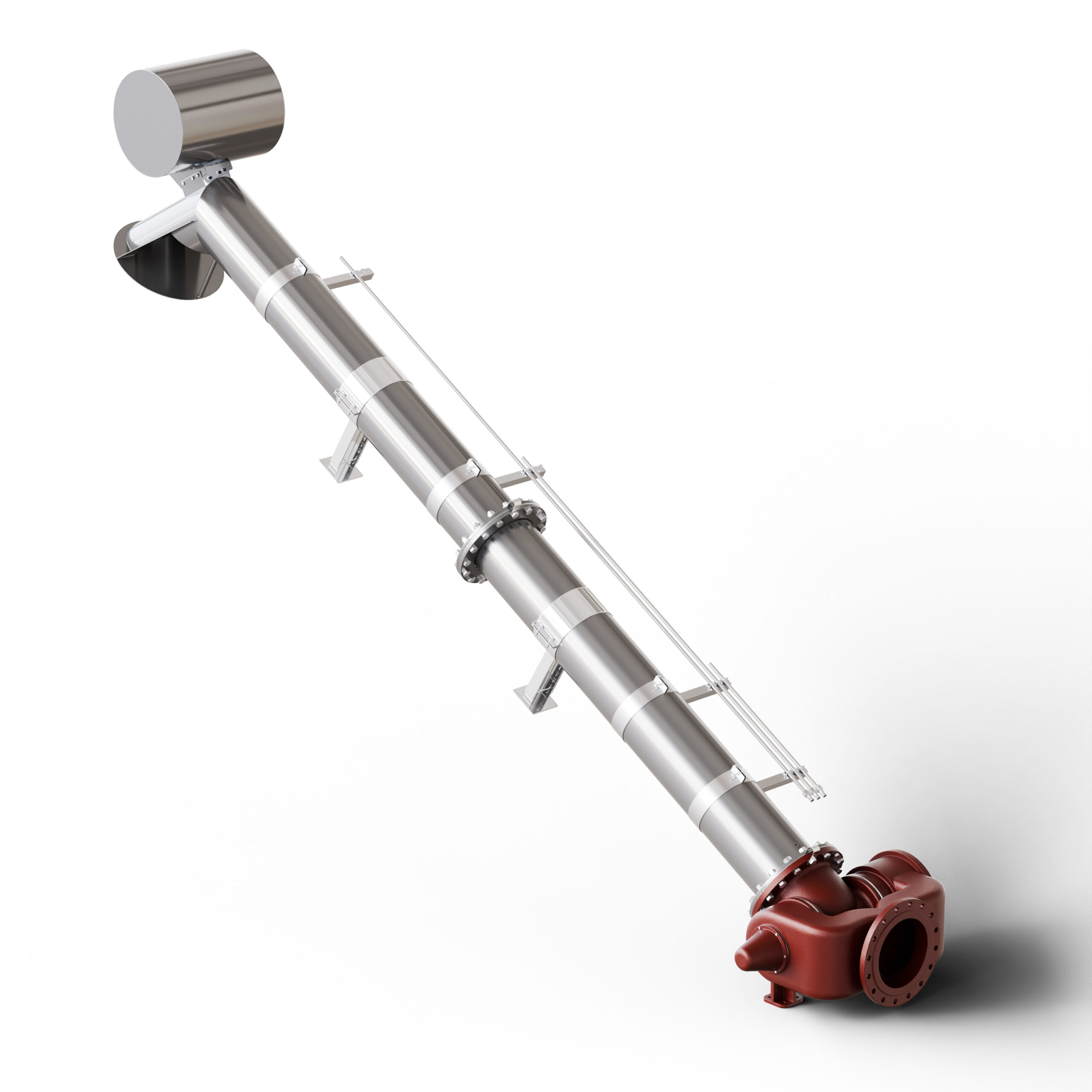

Floating Suction

- Product Integrity & Quality Solution

- Exploitation Boosters

The floating suction system is a withdrawal mechanism designed to extract only the upper layer of liquid stored in a tank. Supported by a float, it remains at the surface and draws the purest part of the product, avoiding any sediments or particles that may settle at the bottom of the tank.

Grounding Reel – RGA750

- Storage Tank Mechanical Equipment

The RGA750 grounding reel is an essential safety device for floating roof tanks. It ensures a low-impedance connection between the floating roof and the tank shell, drastically reducing the risk of electrical arcing and fire in the event of a lightning strike.

High-Pressure Transport Probe (LPG) – DOCIL C 510

- Level Instrumentation for Liquid Storage & Transportation

- Exploitation Boosters

The DOCIL C 510 is a high-pressure level probe designed for pressurized tanks, particularly LPG tank trucks and railcars. Equipped with two integrated optical sensors, it secures filling operations by automatically triggering pump slowdown or shutdown before any overfill occurs, while preserving the gas phase. This enables operators to maximize usable tank volume without compromising loading safety.

Liquid Hydrocarbon Detector – DOCIL HK

- Anti-Pollution Solutions

- Level Instrumentation for Liquid Storage

- Turnkey Solutions for Liquid Storage

The DOCIL HK hydrocarbon detector instantly detects the presence of liquid hydrocarbons, even in the presence of water. It provides reliable monitoring of sensitive areas such as containment basins, decanters, or pumping stations, and triggers an alarm in the event of hydrocarbon detection.

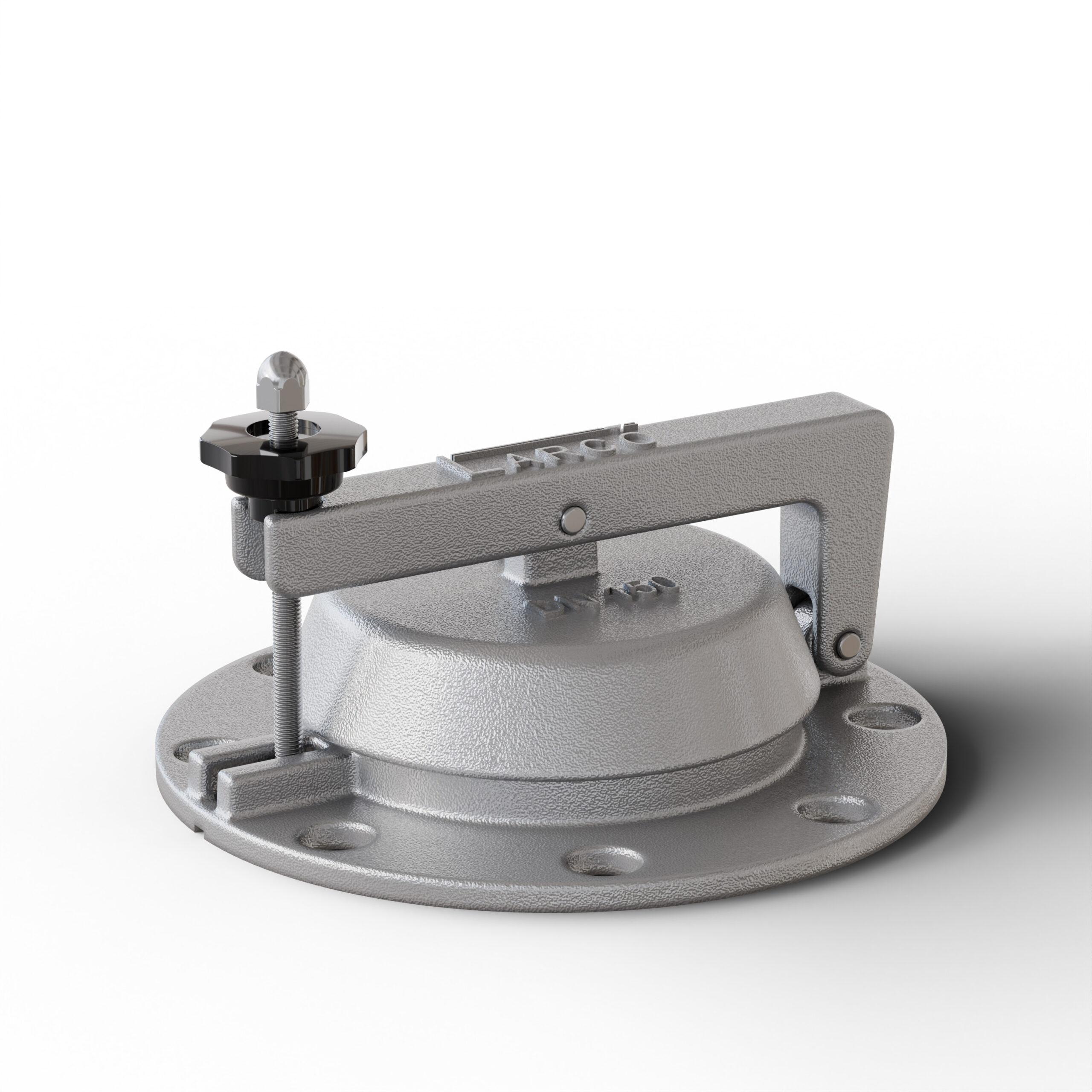

Gauge Pads

- Exploitation Boosters

The gauge pad is a mechanical device installed on the gauge rod vertical, providing quick, secure, and direct access to the product stored in a tank. It facilitates manual gauging by ensuring a reliable entry point compliant with French regulations.

SETMAT

- A complete solution for efficient and secure depots

In a sector where efficiency, safety, and compliance are paramount, SETMAT provides a comprehensive response to the challenges faced by depots. Our advanced ERP, DPPACK, along with our intelligent loading bay equipment, optimizes stock management, loading operations, and logistical flows, while ensuring flawless traceability.

Thanks to its modular and scalable approach, DPPACK adapts to all types of infrastructures, enabling operators to gain in productivity, flexibility, and safety.

Gauging Solutions

- Mechanical

- Radar

- Servo-operated

- ATEX

- Multi-protocol

Complete range of level gauges: simple mechanical gauges, level transmitters for mechanical gauges, non-contact radars, motorized servo gauges

Hydrocarbon Separation Valves

- Storage Tank Mechanical Equipment

- Anti-Pollution Solutions

The TOO and TOR hydrocarbon separation valves are designed to automatically separate water from hydrocarbons in tanks, preventing any product spill onto the ground.

Metal-Reinforced Gasket

- Security

- Anti Air Pollution

- Storage Tank Mechanical Equipment

- Exploitation Boosters

The JTC (Compression Plate Gasket) is a sealing solution designed for fixed-roof tanks with internal floating covers and for external floating roof tanks. Thanks to its robust materials and custom-made design, the JTC provides a reliable and durable way to reduce evaporation, protect the environment, and improve site safety.

Coverflote®

Prevents losses and enhances safety

ProductDOCIL 400 – Overfill Prevention Probe

Prevents overflows

Floating Suction

Improves the quality of the extracted product

Liquid Hydrocarbon Detector – DOCIL HK

Instantly detects leaks

Larco Safety Box

Optimized automation control unit

Compression Plate Seal

Reliable and durable solution to reduce evaporation

SETMAT

A complete solution to centralize and optimize your operational processes

From product entry into the depot to its sale, including accounting and customs management — choose SETMAT.

Protecting people

and the environment

through experience

and innovation