Safety

Turnkey Solutions for Liquid Storage

At LARCO, we offer turnkey solutions for the liquid storage sector, specifically designed to meet the demanding safety and automation needs of industrial facilities. Our standardized solutions can be rapidly deployed on-site and configured to perfectly adapt to the specific requirements of each depot or infrastructure. Backed by our extensive experience in the oil and gas industry, we are now extending our expertise to other sectors that require robust and reliable solutions.

Our solutions are designed to automate operations, enhance safety, and optimize depot performance, providing centralized management and optimal efficiency.

Thanks to our expertise, we integrate our equipment and solutions directly on your sites, enabling a gradual and seamless upgrade of your facilities:

Ensure operational safety

Accurate and reliable detection instruments.

Optimize the management of liquids and gases

Advanced automation solutions.

Integration with existing equipment fleet

Ensure on-Site compliance

Our equipment is ATEX and SIL certified.

Simplified installation, fast maintenance

68 years of expertise

High-Quality Instrumentation

Our solution seamlessly integrates with other essential safety equipment, including vapor/gas detectors, pumps, valves, and automation systems.

Comprehensive Safety Supervision

We provide a centralized solution that enables efficient and integrated control of all your safety equipment.

Seamless Integration

Our solution effortlessly integrates with other essential safety equipment, including vapor/gas detectors, pumps, valves, and automation systems.

Advanced Automation

We design and implement cutting-edge automation for your depot safety management system, ensuring optimal performance and safety.

Comissioning & Testing

Our team manages the entire commissioning process and conducts rigorous testing to ensure everything operates flawlessly.

Maintenance & Support

We provide ongoing maintenance services to ensure the long-term reliability and optimal performance of our instruments.

Safety

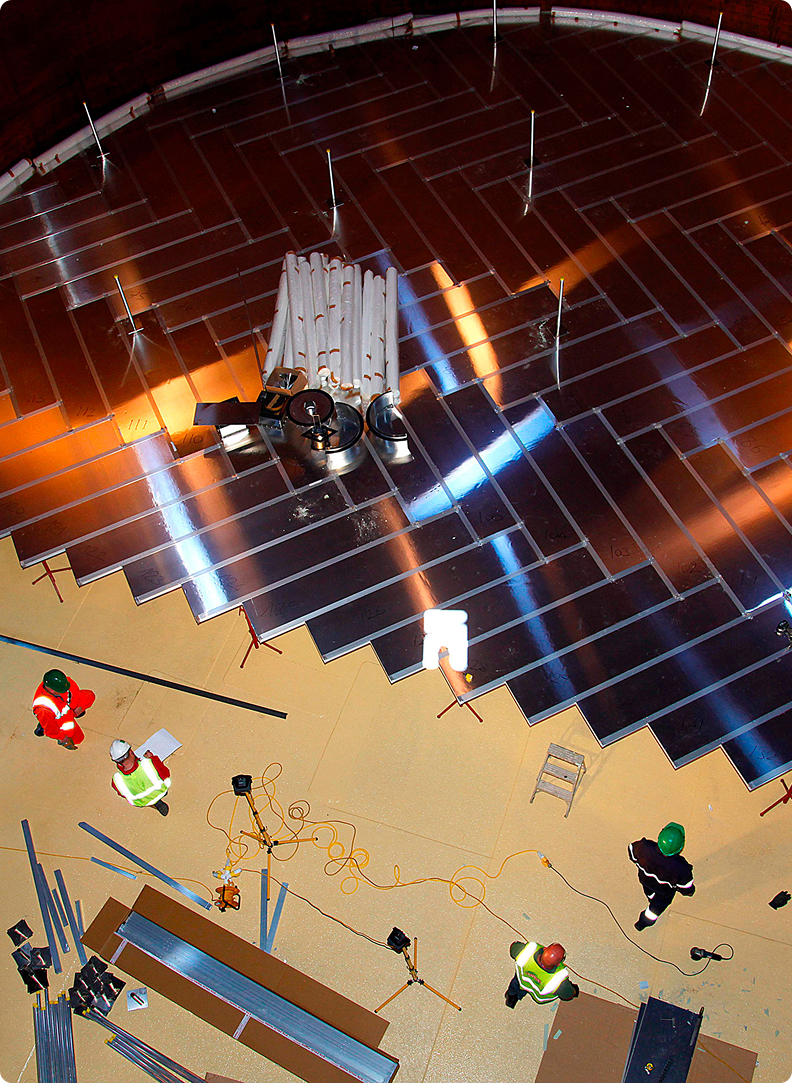

Mechanical Equipment for Storage Tanks

Mechanical equipment in storage tanks plays a crucial role in maintaining the safety, operational performance, and regulatory compliance of industrial facilities. At LARCO, we design robust and durable solutions specifically tailored to ensure the reliable operation of storage tanks.

Ensuring Reliable Tank Operation

Reliable equipment is essential to maintain operational stability, minimize the risk of incidents, and ensure regulatory compliance.

Enhancing Overall Depot Safety

By minimizing the risks of leaks, overpressure, and accidents related to flammable gases, this equipment plays an active role in securing industrial facilities.

Adaptability to ATEX Environments

Our equipment is designed to operate safely in explosive atmosphere zones, ensuring maximum reliability even under extreme conditions.

Safety

Level Instrumentation for Liquid Storage and Transport

Accurate liquid level management is crucial to ensure the safety of industrial facilities and the optimization of logistical operations, both in storage and transport. At LARCO, we design reliable level instrumentation solutions tailored to demanding environments and diverse applications.

Facility Safety

Real-time detection of critical level thresholds (high, very high) and high-flow leaks is a strategic lever to prevent major incidents, ensure operator safety, and preserve the integrity of facilities.

Optimizing LPG Transport

The 510 probe not only ensures safety during the transport of pressurized liquids, but also optimizes the loading of tank trucks and trains by minimizing underfilling while respecting safety margins for substances like LPG.

Cutting-Edge Technology

Thanks to innovations such as DOCIL technology, our probes deliver ultra-fast response times (~0.1 ms) and exceptional accuracy (up to 1 mm), ensuring unmatched performance.

Performance & Operational Excellence

Operational performance accelerators

In a constantly evolving industrial environment, boosting operational performance is a key challenge to ensure the profitability and reliability of facilities. At LARCO, we offer solutions designed to minimize product losses and enhance process efficiency. Our equipment has proven particularly well-suited to the needs of airport depots, oil storage terminals, and the food and beverage industry.

Minimizing Product Losses

Our solutions significantly reduce losses caused by evaporation and leaks, ensuring improved profitability.

Storage Space Optimization

With innovative equipment, we help maximize tank capacity while maintaining high safety standards.

Operational Efficiency and Speed

Our solutions help reduce product handling time and enhance logistical operations.

Performance & Operational Excellence

Solutions for Product Integrity and Quality

Preserving product integrity and quality is a critical challenge in industries where liquid purity and storage safety are paramount. At LARCO, we develop solutions designed to minimize losses, maintain product purity and integrity, and ensure optimal storage conditions.

Preserving Product Purity and Integrity

By minimizing the risks of contamination and oxidation, we ensure the quality of sensitive products such as JET A-1, SAF, and liquid food products.

Performance & operational excellence

SETMAT: ERP & Loading Dock Equipment

SETMAT is much more than an ERP. It is a comprehensive solution that combines depot management software with physical loading bay equipment. Designed to meet the needs of complex logistics industries, SETMAT optimizes productivity, enhances operational traceability, and strengthens the safety of loading processes.

SETMAT solutions are designed to seamlessly integrate with your existing infrastructure, while offering maximum flexibility to meet the specific needs of each site.

Logistics Flow Optimization

SETMAT helps reduce waiting times, improve queue management, and streamline loading/unloading processes through advanced planning tools.

Increased Productivity

Automation of repetitive tasks, intelligent driver appointment management, and real-time operation monitoring ensure optimal performance.

Enhanced Safety

Integration of safety features such as biometrics, secure access control, and real-time alarm management to protect both facilities and personnel.

Traceability and Compliance

Accurate management of inventory, product flows, and customs documentation, facilitating regulatory compliance.

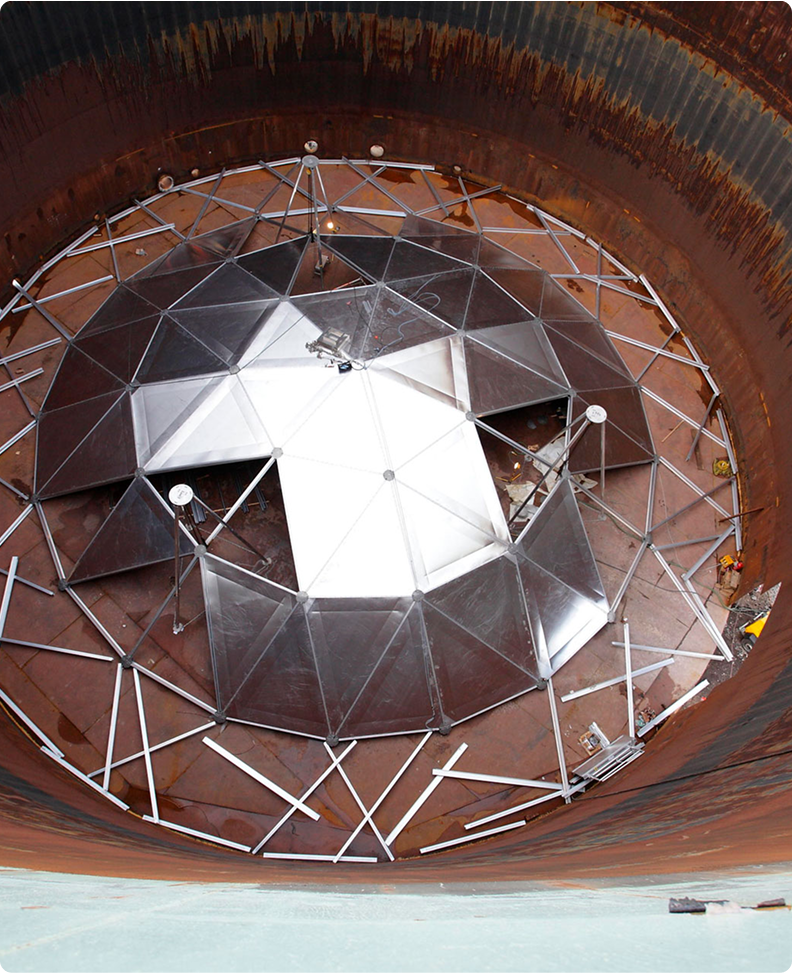

Environnement

Solutions Anti-Pollution

Managing air emissions and soil pollution is a critical challenge for the hydrocarbon storage industry. At LARCO, we offer innovative solutions to effectively reduce VOC (Volatile Organic Compound) emissions and robust systems to prevent overflows and liquid leaks that could contaminate the soil—contributing to environmental protection and regulatory compliance.

VOC Emissions Reduction

Our equipment reduces liquid evaporation by up to 99%, minimizing product losses, limiting air pollution, and enhancing environmental quality.

Liquid Leak Prevention

Our equipment is designed to quickly detect any potential leaks and minimize the risk of soil contamination.

Infrastructure Safety

By reducing the risk of leaks, we help protect infrastructure, safeguard personnel, and ensure the safety of industrial operations.

Protecting people

and the environment

through experience

and innovation