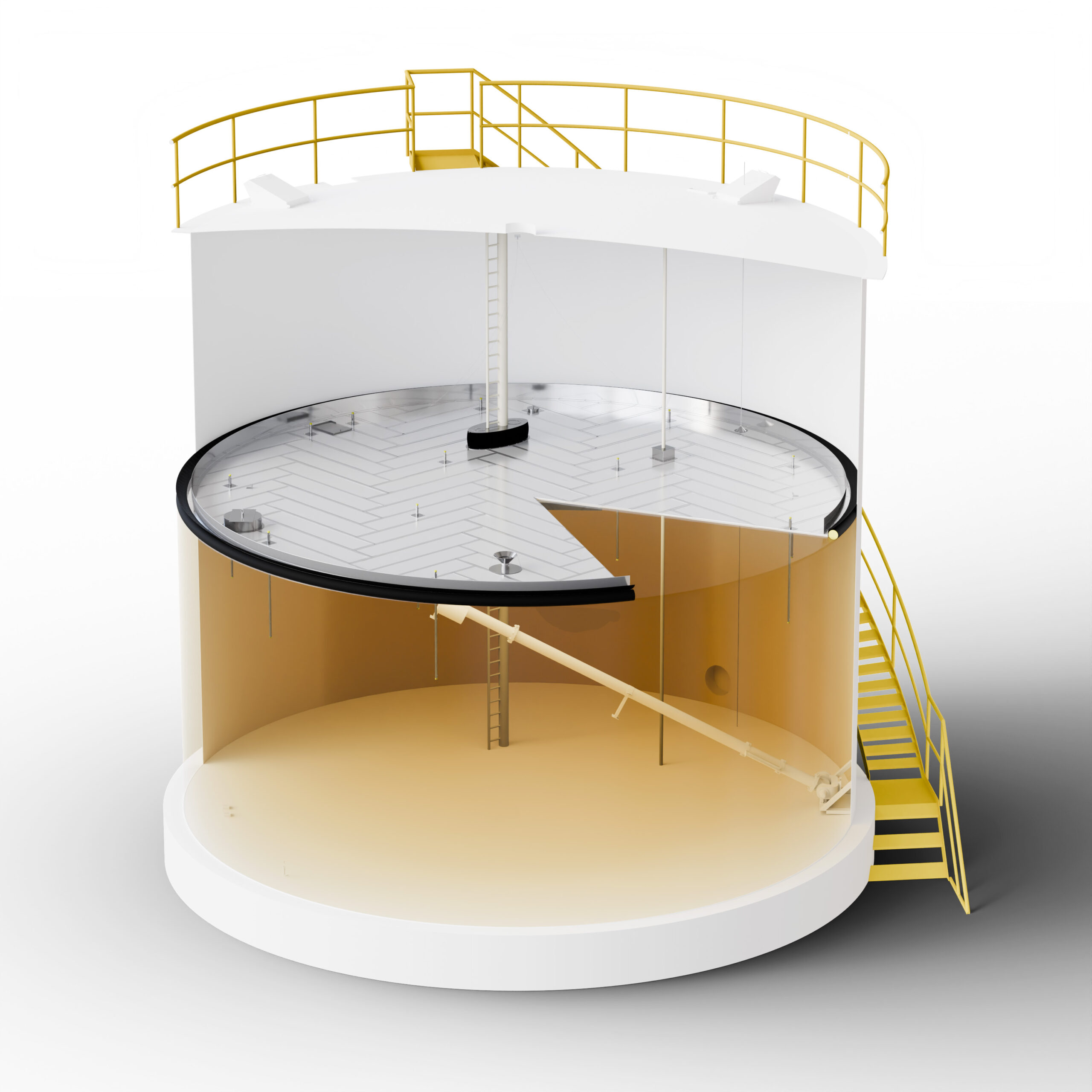

Floating Screen: COVERFLOTE

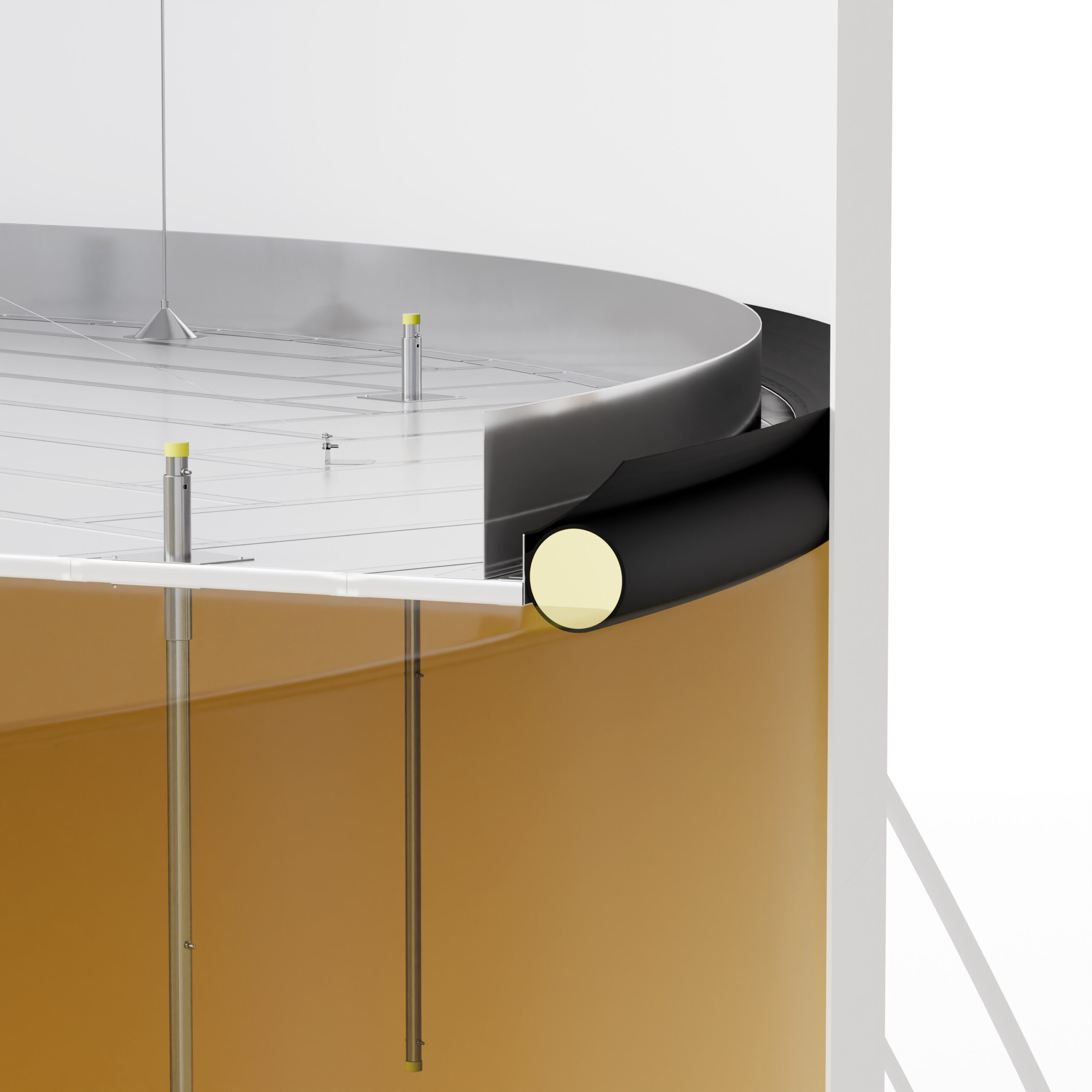

The COVERFLOTE® is an internal floating screen designed for installation in fixed-roof tanks containing liquids that may evaporate or oxidize upon contact with air. Composed of self-floating panels, the COVERFLOTE® maintains continuous contact with the liquid surface, thus preventing the formation of a gas phase between the panels and the product. Its peripheral seals compensate for tank imperfections. This design reduces product evaporation by up to 98%, thereby lowering volatile organic compound (VOC) emissions and enhancing both site safety and financial efficiency.

Benefits

- Enhances tank safety by limiting the formation of gas phases, thereby reducing explosion risks.

- Significantly reduces VOC emissions, achieving up to 98% reduction in evaporation losses.

- Maximizes financial efficiency with its low profile design, allowing optimal use of storage capacity.

- Highly adaptable, even in unforeseen situations: panels are custom-cut to the tank’s specifications without affecting buoyancy.

- Minimizes downtime: COVERFLOTE® is assembled without welding, and all components fit through a 24-inch manhole.

- Maintains product purity while minimizing unpleasant odors.

Avantages

Installation

All COVERFLOTE® components are designed for direct insertion through the manhole, requiring no modifications to the tank structure or hot work. Additionally, these standard, stocked components enable fast on-site delivery, significantly reducing tank downtime.

Technology

The COVERFLOTE® consists of polyisocyanurate foam panels laminated between two aluminum sheets. This design provides the panels with enough rigidity to support the weight of three people walking on them.

The panels are then fitted into aluminum profiles and assembled with bolts, eliminating the need for hot work.

Testability

The COVERFLOTE® requires no tightness testing during operation, as its panels ensure complete buoyancy.

Moreover, the tank does not need to undergo tightness testing since the COVERFLOTE® installation involves no hot work.

Options

- A wide range of accessories is available to adapt to the specific design of the tank.

- Materials are selected according to the stored product to ensure optimal compatibility.

Certifications

- Compliant with CODRES requirements and API 650 standards.

- Available in a certified version compatible with food-grade products.

Key information

- Tank diameter

- Details of nozzles

- Geometric survey

- Type of stored product

Success Story