Process and safety automation for oil depots

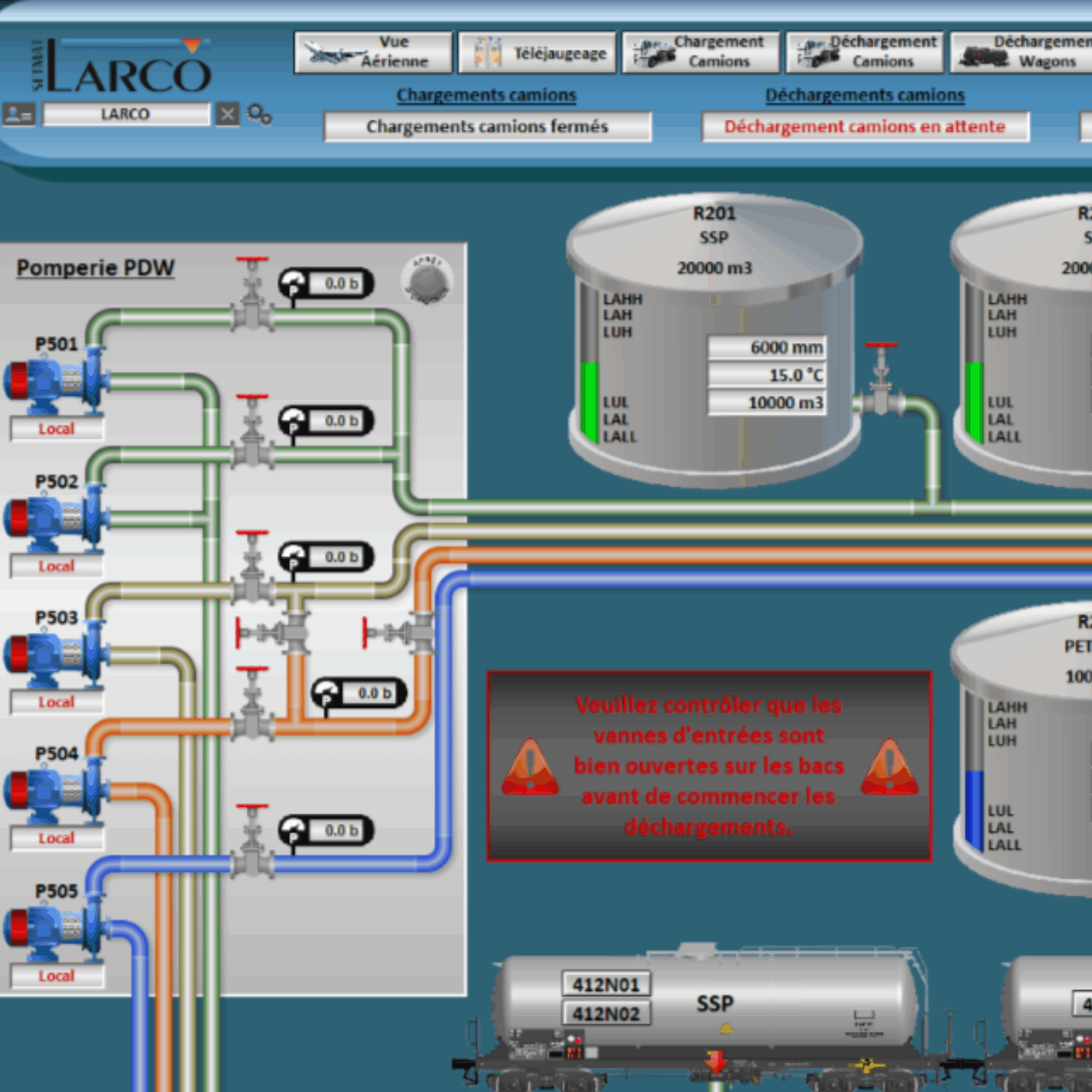

LARCO designs custom automation systems to optimize and secure the facilities and operations of oil depots. Using programmable logic controllers (PLCs), human-machine interfaces (HMIs), and supervision solutions, we provide a comprehensive and perfectly tailored response to the site's specific requirements and operational constraints. Our expertise covers both safety automation and process control, with remote access capabilities via a connected gateway.

Your needs on demand

Process Automation

- Pipeline Reception

Software application designed to secure, ensure reliability, and synchronize product receptions via pipeline. - Ship Reception

Software application to secure, ensure reliability, and synchronize product receptions by ship. - Train Reception

Software application to secure, ensure reliability, and synchronize product receptions by train. - Pump Control

Software application enabling:

– Secure and optimized control/command of pumps

– Management of start counts and cycles

– Reassignment of pumps without changes to control cabinets

– Pump-to-tank linking

– Parallel operation of pumps to increase flow rate - Valve Control

Software application for controlling/commanding motorized valves via wired or fieldbus connections. Prevents unintended movements, executes and logs open/close commands, and measures valve operation times. - Web Control

Software enabling remote visualization of supervision data through a standard web browser without special PC configuration. - Additivation and Coloring

Software for injecting additives or colorants during truck loading. - Remote Gauging

Software integrating any type of gauging system with data displayed on the supervision platform. - Fire Protection

Automation solution for automatically activating fire-fighting equipment. Compliant with regulatory requirements and multi-zone scenarios. - Ethanol / Additives / Product Unloading

Automation solution for automatic unloading of products, ethanol, or additives via truck or barge. - Remote Access (Smart Connect)

Physical device enabling remote control of the PLC, HMI, and supervision functions. Ideal for troubleshooting, updates, or remote assistance without onsite technician intervention. Connection secured by a physical authorization key and IT security compliant with standard XXX. - Automatic Mailing

Web option for automated email report sending. Content, frequency, and recipients fully customizable. Compatible with gauging data, safety indicators, or other operational metrics (e.g., daily stock status at 6 PM). - SMS Alert Module

Automatic SMS alert sending to operators, customizable based on needs.

Safety Automation

Our teams are certified in programmable logic controller (PLC) programming following industry best practices (Schneider, Siemens, Kep, Arc Informatique).

We also manage and fully integrate safety equipment, whether supplied by LARCO or third parties (such as gas and flame detection solutions).

Our solutions are designed for easy integration with your existing environment, regardless of brand or communication protocol.

We ensure full interoperability with market equipment thanks to our expertise in standard industrial communication protocols (Modbus RTU/TCP, Profibus, Profinet, 4-20mA HART, etc.) and experience with leading industry brands.

We also meet safety requirements, particularly for Instrumented Risk Measurement and Control (MMRI). To maintain a high level of safety and reliability, we offer SAFETY PLC architectures that ensure SIL 2 or SIL 3 levels across the entire safety chain.

We implement methods to ensure high availability of installations, including:

Redundant PLC architectures

Ring communication networks

Integration of network self-healing functions

Our knowledge and expertise in the oil sector enable us to meet all client needs for automation and safety management of oil depots.

Avantages

Installation

We provide complete systems, ready for on-site integration, including all necessary components:

Supervision stations

Standard or custom control cabinets

HMIs, PLCs, communication modules, and more

Each installation is customized based on the site’s actual configuration and the client’s functional requirements.

LARCO teams also handle on-site commissioning, ensuring compliant and fully operational installations, along with knowledge transfer to operational teams.

Benefits

- Custom Solution Tailored to Each Client Configuration

- Certified process and safety automation (safety certification, programming best practices)

- Multi-brand expertise (Schneider, Siemens, Kep, Arc Informatique, etc.)

- Multi-protocol communication (Modbus RTU/TCPIP, Profibus, Profinet, etc.)

- Intelligent alert modules (SMS, automated emails, remote supervision)

- Comprehensive support: audit, study, development, commissioning, training, maintenance

- Maintenance & remote support via Smart Connect gateway

Technologie

- Factory Acceptance Testing (FAT)

- Cross-Reviews

- Site Acceptance Testing (SAT)

Certifications

- SIL 2 / SIL 3 depending on the installed equipment

Success Story